How To Build A Reverse Flow Smoker

So, yous plan to build an first smoker? Congrats! It'due south a large undertaking, but fun and educational. This page is idea to be your guide when building your own offset smoker.

Background

I'yard an abet for what is ordinarily known as 'fat-stack' smokers. Being an engineer means calculating and measuring, instead of merely guessing. A smoker needs to breathe properly. Below follows a detailed walkthrough of all parts of a smoker, regardless of whether it is a normal one or a reverse menstruum smoker. I discuss what you need to remember of, and besides what can be ignored. My aim is to take away some of the guesswork and myths when it comes to edifice get-go smokers. This is my manifesto.

How it works

An starting time smoker is typically using wood as a fuel source. 'Offset' means the burn is showtime, typically sideways, then you become the indirect oestrus setup that is key to barbecue.

There are roughly two types of start smokers.

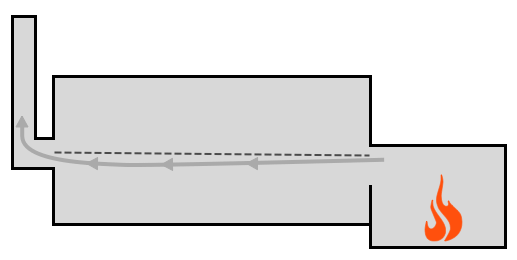

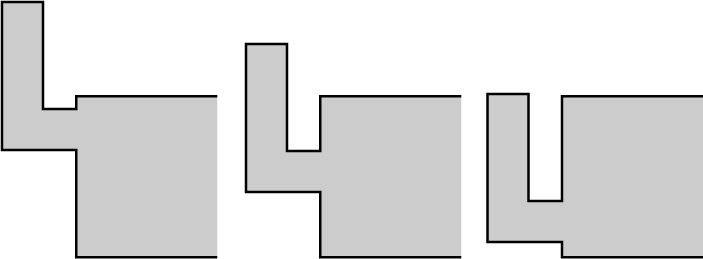

Normal offset smoker

As y'all can see from the analogy above, the fire is in the firebox to the right. Hot air and smoke travels through the nutrient bedchamber and out through the smoke stack. This is a 'simple' design that works well. Depending on how information technology is synthetic it naturally runs hotter in the firebox end of the food sleeping room but this tin be compensated for. If you don't experience like building one only instead want to purchase ane then Hank'south Truthful BBQ is manufacturing top quality pits. Take a look here!

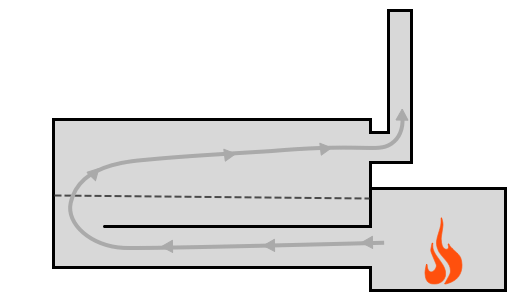

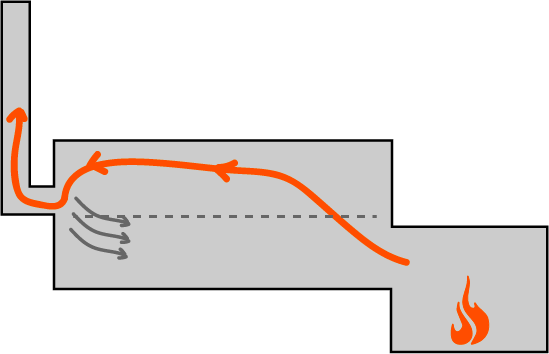

Reverse Flow Start Smoker

As illustrated the reverse flow smoker uses a long baffle to move air all the way through the food bedroom before being turned around, or reversed. This helps even out temperature differences since the radiant estrus from the baffle and food sleeping accommodation walls heat up the air more evenly. The drawback is that air must travel longer, thereby potentially reducing typhoon if it isn't dimensioned properly. The most obvious sign of a opposite catamenia offset smoker is the chimney being mounted on the same side as the firebox. If you don't feel similar edifice one but instead want to buy i and so Hank's True BBQ is manufacturing acme quality pits. Take a look here!

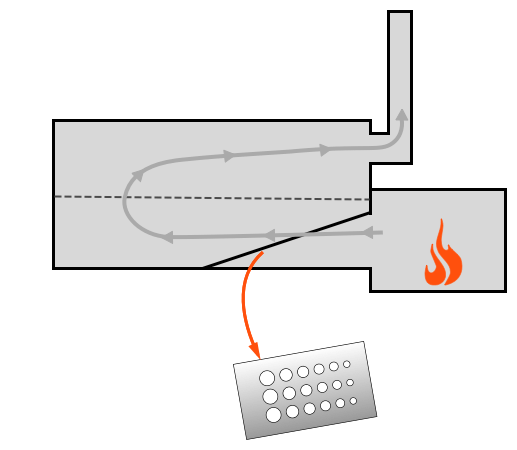

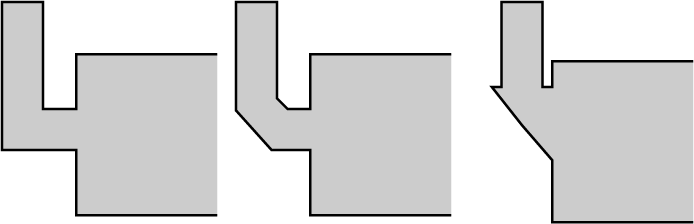

Contrary Flow Start Smoker – a unlike version

The chief idea behind contrary menses is (as mentioned) to reduce temperature differences in the food chamber. Completely depending on different constructions an first smoker is typically hotter the closer to the fire yous get. A mutual fashion to solve this is to use a slanting baffle perforated with different size holes. Run across picture above. The hot air flow is slightly redirected by the smaller holes at the peak, forcing some of the hot air downwardly where the larger holes are. This distributes heat more evenly when it enters the food chamber. Ane must remember that air moves a lot faster through an offset smoker than in your ordinary kettle or kamado.

If unsure of which to build, start with a normal offset smoker, due to a simpler construction. That being said the opposite menses pattern suits smaller smokers improve since the BTU (energy) in is wood high. You get slightly more even temps with the reverse flow in a small smoker.

NOTE: many first time builders I talk to have their mind set on building a opposite flow smoker since they only 'know' information technology is amend. And that without even having used i, reverse flow or not. I think that is largely due to the many inexpensive beginning smokers available on the market place, which are badly designed and have big temp swings. A well constructed offset smoker has no bug with temp swings. My offset smoker 'Rude Boy' is a normal flow smoker, and I have a v-8 degree temp variance in the food chamber. That is style less than almost contrary flow smokers commercially available.

The Nutrient Sleeping accommodation

Beginning with the food sleeping accommodation and calculate the rest of the smoker appropriately. Size and shape is governed mainly by two things:

- Capacity. How much food practice you lot need to cook at once?

- Appearance. What mode of smoker are you lot looking for?

Several grates at unlike levels are very common, besides equally different door mechanisms. I usually measure briskets and ribs with a folding dominion to be able to estimate shelf size. Make certain you measure out height also to get a correct vertical distance between shelves. Regardless of size, two shelves/grates are recommended. This is to go more cooking chapters, but the temps will also be a little different (hotter on the higher grates), and this can be advantageous when smoking different cuts of meat at the aforementioned time.

The Firebox

The firebox needs good oxygen supply, and should have room for building a good fire with 5-six logs. The purpose of the firebox is to create a burn that tin warm upward and hold temp in the food chamber. The size of the firebox is not related to the size of the food chamber. Why not, you may ask? Well, the rut energy in burning wood is and then high that even a iv-5 log fire tin can sustain temps in a 1000 gallon smoker. There are diverse suggestions online to make the firebox a certain pct size of the food chamber, but that simply doesn't concord true. Accept a look at actually large smokers like the ones Aaron Franklin buids, and there you will see the firebox is relatively pocket-sized.

Firebox Size

In general, the firebox can exist smaller than you retrieve. Pure wood has college BTU (heat free energy) than charcoal or briquettes, and then even a small burn down volition produce plenty estrus. When I build a firebox I make a cardboard box every bit a model offset. It saves a lot of time and measurements. If unsure, commencement with a firebox that is 50 cm wide, 50 cm tall, sixty cm deep (20″ wide, twenty″ tall, 24″ deep). That size will suit most backyard size smokers. The reason for having it slightly longer is to let for it to protrude into the firechamber, but as well to be able to build your fire further in (common during winter) or closer to the door.

Is in that location such a affair as also small a burn down box? Aye if the fire box is too pocket-sized you will have bug with temp spikes in the nutrient chamber. A sure size fire box gives you a bigger thermal mass (bigger fire box -> more metal), and also a larger buffer of hot air. Hence the general proposition on size in the previous paragraph.

Fume Stack Size

In lodge for an offset smoker to piece of work well you need a clean burning burn. A clean burning fire requires expert draught, which is accomplished with an appropriately sized smoke stack. Many commercial smokers take a smoke stack that is too thin and/or also short if you ask me. The smoke stack is the engine in your smoker. By draught I mean the amount of air beingness pulled through the smoker, measured in ft3/s, or m3/due south if you use the metric system.

A common misconception online is that the smoke stack should exist sized co-ordinate to the size of the food chamber or fire box. This is wrong. Draft is primarily controlled by diameter and length of smoke stack – within reasonable limits, see below.

The size of the smoke stack is governed past how much natural draught you lot desire. Natural draught is controlled by the temperature difference betwixt the food chamber and the outside air. That holds truthful within reasonable limits.

What do I mean past that? Well, imagine a correctly dimensioned smoke stack for a 500 gallon smoker measures ten″ in diameter and is iii meters tall. Now put that on a backyard size smoker – would that still produce the same typhoon? No, because the volume of the smoke stack is so much larger in relation to the nutrient bedchamber. In this scenario the smoke stack needs to be scaled down proportionally.

Smoke Stack Placement

Most smoke stacks are located at the very top of one end of the food chamber. Some are centered vertically.

Placement of the fume stack is more important than you lot recollect. In an offset smoker there'southward a lot of hot air moving through at a constant pace. Hot air rises, meaning it volition move up to the pinnacle of the food chamber equally information technology moves across. Past placing the smoke stack lower down on the nutrient sleeping accommodation, the hot air flow will exist temporarily reduced (when forced downwardly), causing some of the hot air to transfer its heat back into the food sleeping accommodation and therefore reduce the temperature differences slightly. Y'all can place the smoke stack even lower than that if you lot want to, simply in my experience information technology doesn't help. See the epitome below which illustrates this back pressure.

For contrary flow smokers the smoke stack is mounted high. Due to air traveling longer in the food bedchamber, you want to improve draft by making information technology equally easy every bit possible to become air from A to B. Besides the effective height of the food sleeping accommodation is reduced with the baffle in identify.

Smoke stack transition (elbow)

The aerodynamically oriented may wonder if the elbow or curve should be every bit smooth as possible to allow the smoker to breathe fully.

Y'all can utilize a ninety degree curve, or 'soften' it a bit in diverse ways. Does it really matter? A 90 degree bend will affect draught slightly, only the issue is then small it can be ignored in this type of application. An offset smoker has a lot college air flow than a kettle grill, but at the same fourth dimension it's not a Formula ane car either. Choose what is piece of cake to build or that matches the look you're after. I bought a smoothly bent (1/4 circle) pipe myself, information technology was the easiest way for me.

Materials – what to employ

Regular steel is by far the virtually mutual textile. It is mostly available, and affordable. Stainless works just as well, but comes with a much higher price tag. The one material to steer clear of is galvanized steel. it contains a lot of zink (a natural role of the galvanization process), and information technology releases toxic gases when heated. Some may counter by maxim that the temp in the food bedchamber is too depression for the zink to evaporate, simply the fire temperature in the fire box is a lot higher than that, and so avert galvanized steel at all times.

General construction ideas

The opening from the firebox into the nutrient chamber should be as large as, or bigger than, the smoke stack size. This is to avoid throttling the air flow. So: if you 'walk' the path the air takes, but backwards, from the smoke stack to the firebox, each opening/aperture the air passes should be equal to, or bigger than, the previous opening/aperture.

How to manage your smoker fire

Source: https://hankstruebbq.com/hanks-offset-smoker-manifesto/

0 Response to "How To Build A Reverse Flow Smoker"

Post a Comment